LMF340

Description:

The inductive proximity switch consists of three parts: an oscillator, a switching circuit and an amplifier output circuit. The oscillator generates an alternating magnetic field. When the metal target approaches this magnetic field, and the induction distance is reached, eddy currents are generated in the metal target, which causes the oscillation to decay and even the vibration to stop. The changes of oscillator oscillation and stop vibration are processed by the post-amplifier circuit and converted into a switching signal, which triggers the drive control device, so as to achieve the purpose of non-contact detection. The closer the target is to the sensor, the greater the damping in the coil, and the greater the damping, the lower the current of the sensor oscillator.

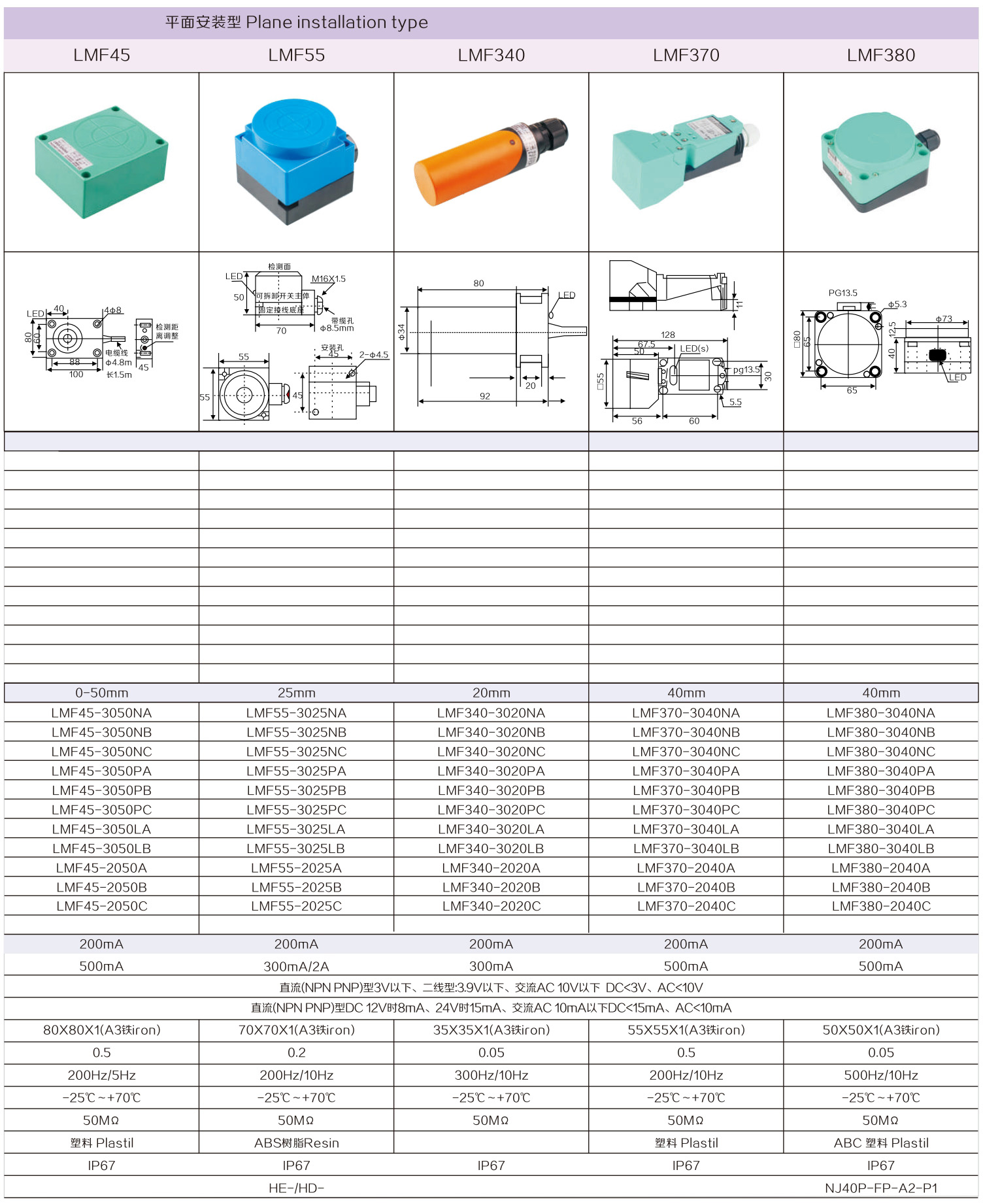

- Type and Specification